Customer Services

Copyright © 2025 Desertcart Holdings Limited

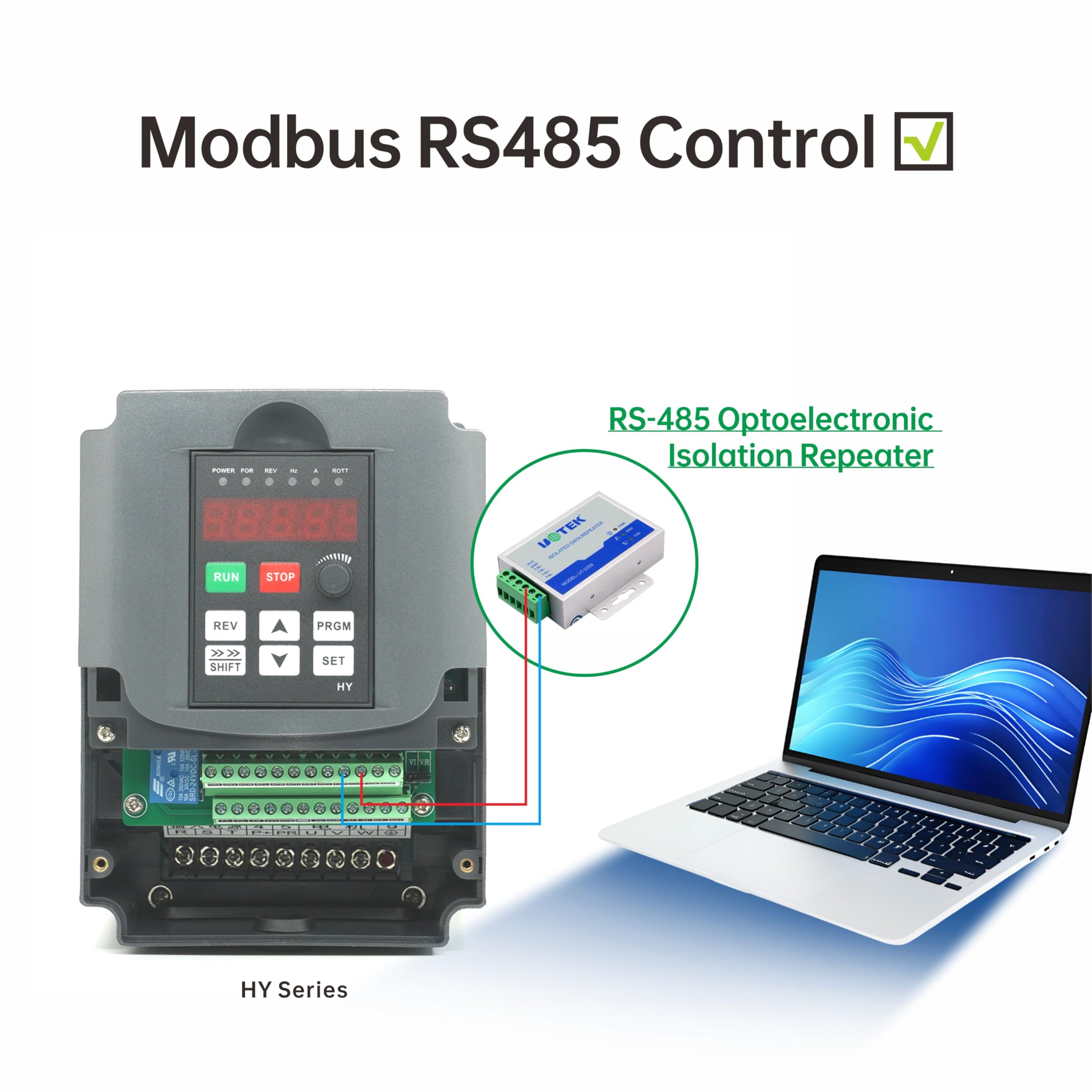

★★critical video link→ https://youtu.be/XVvDsdHq1OQspecification:modle:HY01D523Bpower:1.5KWhorsepower:2HPInput voltage:single-phase or three-phase 220V + -15% 50Hz / 60HzMaximum output voltage:0 to 220V three-phaseMaximum output frequency:0 to 400hzThe functional range can be set:PD000 to PD183NOTE:●the product can work with 220V single phase input and 220V three phase input.you can just connected L1/L2 to any two of VFD input R/S/T●The item is not fit for capacitance motor(single phase motor)Feature: ●Our item adopts the Japan Mitsubish chip. ●PID control; advanced calculous PID closed-loop arithmetic, quick responding speed and high suitability. ●Easy PLC function can realize 16 legs of speed and inverter control function. ●RS485 communication port, adopting standard international MODBUS main circuit control. ●With extremely strong anti-jamming capability. ●Low output ratting torque, low speed running ability. ●Carrier adjustable by 16KHZ, completely soundless working environment. ●Broad voltage working area. ●Auto voltage regulation (AVR) technique, for ensuring the inverter load capability. ●Various control technique by both synchronization and non-synchronization, dynamically realize fast starting without changing brakes.Applicable spindle motor:https://www.desertcart.com/dp/B077C29RXB?th=1 Review: HUANYANG VFD HY01D523B 1ph in 3ph out 0-220 vac 1.5Kw (2hp) 0.50hz- 400.0hz Output current 7.0 A Motor Leeson C184T11FB10C 3ph 208-230 v 60 Hz 2 Hp (1,5kw) FLA 7.2 SFA 7.8 Eff. 86.5% 6 Poles Notes: VFD Settings varies from a company to another Steps for programming the parameters. 1) Press “Program” 2) Press “Up” or “Down” arrows to get to the parameter you want. 3) Press “Set” to select the parameter for editing. 4) Press “Up” or “Down” arrows to enter the setting you want. 5) Press “Set” to lock in the new parameter value *Note: The “Shift” button changes the input position from right to left across the display. Parameter Value My Explanation PD000 0 0 = Allows VFD parameters to be adjusted 1 = Prevents VFD parameters from being adjusted PD013 0 8 = Reset VFD to factory settings (if necessary) PD001 1 0 = Start/Stop motor by buttons on the front of the drive. 1 = Start/Stop motor by external switch 2 = Start/Stop motor by computer communication port" PD002 1 0 = Motor Speed adjusted by buttons on the front of the drive 1 = Motor Speed adjusted by potentiometer (Onboard or external, jumper on “VI” for external or “VR” for onboard) 2 = Motor Speed adjusted via computer communication port" PD005 60 The maximum frequency that the drive will send to the motor. PD004 60 Rated frequency of the motor as listed on the motor's nameplate. PD003 60 The frequency (speed) the motor starts off at when PD002 is set to 0 . PD008 220 Rated voltage of the motor as listed on the motor's nameplate PD014 2.0 Time in seconds for motor to accelerate to full speed. PD015 2.0 Time in seconds for motor to decelerate to complete stop. PD023 1 0 = Reverse motor rotation not allowed. 1 = Reverse motor rotation is allowed. PD070 0 0 = 0-10V for external potentiometer Ref PD002 PD072 60 Higher analog frequency Same as PD005 (Factory set a 400hz not 50hz) PD141 220 Rated voltage of the motor as listed on the motor's nameplate. PD142 7 Set it to VFD max rating. F.L.A. (Full load amp) rating of the motor as listed on the motor's nameplate. PD143 6 Number of poles = 120(f)/n where f = motor's rated operating frequency (60Hz in the USA) and n = motor's rated RPM on the nameplate. 120 factor x 60 HZ divide by 1165 rpm = 6,180 rounded to 6 PD144 1165 Rated RPM of the motor as listed on the motor's nameplate. Review: I have 4 of these operating pumps 24/7 365 since 2020. They are in a hot environment, so I have a 4" computer style fan laying on top of each controller drawing up to assist with heat management. The internal fan is probably not up to this task once the heat sinks become dirty after a year or two. Heat kills silicon, so it is well worth the extra $10 investment for an external fan. I am using external control of speed and also using another input as a safety fallback to keep the pumps idling at 20hz in the case of a blockage or other water issue. Make sure they are mounted vertically (as shown in the product photo) for proper airflow.

| ASIN | B0775BKKNJ |

| Guaranteed software updates until | unknown |

| Item model number | HY01D523B |

| Manufacturer | HY HUANYANG |

| Product Dimensions | 17.02 x 12.95 x 16 cm; 1.54 kg |

A**D

HUANYANG VFD HY01D523B 1ph in 3ph out 0-220 vac 1.5Kw (2hp) 0.50hz- 400.0hz Output current 7.0 A Motor Leeson C184T11FB10C 3ph 208-230 v 60 Hz 2 Hp (1,5kw) FLA 7.2 SFA 7.8 Eff. 86.5% 6 Poles Notes: VFD Settings varies from a company to another Steps for programming the parameters. 1) Press “Program” 2) Press “Up” or “Down” arrows to get to the parameter you want. 3) Press “Set” to select the parameter for editing. 4) Press “Up” or “Down” arrows to enter the setting you want. 5) Press “Set” to lock in the new parameter value *Note: The “Shift” button changes the input position from right to left across the display. Parameter Value My Explanation PD000 0 0 = Allows VFD parameters to be adjusted 1 = Prevents VFD parameters from being adjusted PD013 0 8 = Reset VFD to factory settings (if necessary) PD001 1 0 = Start/Stop motor by buttons on the front of the drive. 1 = Start/Stop motor by external switch 2 = Start/Stop motor by computer communication port" PD002 1 0 = Motor Speed adjusted by buttons on the front of the drive 1 = Motor Speed adjusted by potentiometer (Onboard or external, jumper on “VI” for external or “VR” for onboard) 2 = Motor Speed adjusted via computer communication port" PD005 60 The maximum frequency that the drive will send to the motor. PD004 60 Rated frequency of the motor as listed on the motor's nameplate. PD003 60 The frequency (speed) the motor starts off at when PD002 is set to 0 . PD008 220 Rated voltage of the motor as listed on the motor's nameplate PD014 2.0 Time in seconds for motor to accelerate to full speed. PD015 2.0 Time in seconds for motor to decelerate to complete stop. PD023 1 0 = Reverse motor rotation not allowed. 1 = Reverse motor rotation is allowed. PD070 0 0 = 0-10V for external potentiometer Ref PD002 PD072 60 Higher analog frequency Same as PD005 (Factory set a 400hz not 50hz) PD141 220 Rated voltage of the motor as listed on the motor's nameplate. PD142 7 Set it to VFD max rating. F.L.A. (Full load amp) rating of the motor as listed on the motor's nameplate. PD143 6 Number of poles = 120(f)/n where f = motor's rated operating frequency (60Hz in the USA) and n = motor's rated RPM on the nameplate. 120 factor x 60 HZ divide by 1165 rpm = 6,180 rounded to 6 PD144 1165 Rated RPM of the motor as listed on the motor's nameplate.

P**H

I have 4 of these operating pumps 24/7 365 since 2020. They are in a hot environment, so I have a 4" computer style fan laying on top of each controller drawing up to assist with heat management. The internal fan is probably not up to this task once the heat sinks become dirty after a year or two. Heat kills silicon, so it is well worth the extra $10 investment for an external fan. I am using external control of speed and also using another input as a safety fallback to keep the pumps idling at 20hz in the case of a blockage or other water issue. Make sure they are mounted vertically (as shown in the product photo) for proper airflow.

G**X

Works well on Bridgeport clone. I have it locked to 60hz because I’m using a Varispeed. The motor doesn’t see designed to cool at low speeds so I won’t be using variable frequency until I replace w good Baldor

R**T

Je ne m'attendais pas à recevoir cet article si rapidement. Bravo. Paquet bien emballé, bonne instruction, il suffit de bien lire tout le document avant d'entreprendre les connections. Très satisfait

J**L

Bought this for an upgrade to my Onefinity CNC router. Not only did I not find any solid information on basic programming parameters, I looked in the manual, which while being written in almost grammatical correctness, it was still like decrypting ancient Egyptian heiroglyphic jokes that were reliant on the situation at the time they were written to understand the information. I've reached out for help in multiple forums and am almost to the point where it is functioning the way it should, but this thing is a monster! Oh! Make sure you don't ever hook the spindle to it before you finish programming and lock the settings!! Multiple forum members have shared horror stories about how they fried their spindle or the VFD simply by making that mistake!

Trustpilot

1 month ago

1 day ago