Customer Services

Copyright © 2025 Desertcart Holdings Limited

🔥 Print Tough, Print Smart — Dominate Outdoor 3D with FLASHFORGE ASA!

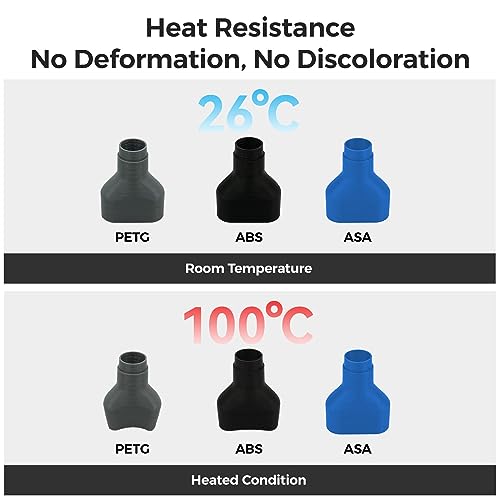

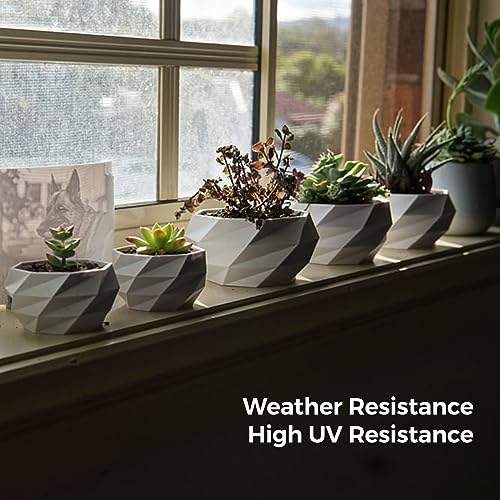

FLASHFORGE ASA Filament is a premium 1.75mm black 3D printing material engineered for durability and precision. Featuring ±0.02mm dimensional accuracy, high UV and chemical resistance, and heat tolerance up to 93°C, it’s optimized for outdoor functional parts. Vacuum-sealed and pre-dried, it guarantees clog-free, bubble-free printing, making it the go-to choice for professionals demanding reliability and performance.

| ASIN | B09V7HG9DR |

| Best Sellers Rank | #3,931 in Industrial & Scientific ( See Top 100 in Industrial & Scientific ) #238 in 3D Printing Filament |

| Date First Available | February 21, 2022 |

| Item Weight | 2.2 pounds |

| Manufacturer | Zhejiang Flashforge 3D Technology Co., Ltd. |

| Product Dimensions | 7.87 x 7.87 x 2.56 inches |

S**.

Wonderful

TLDR: Enclosure, good hotend and a regular ass ender 3 from 2021 can print this beaufully... even if your encoding is a big cd m cardboard box. It prints very rigid, VERY rigid but is it just as strong. Keep realistic expectations in your settings and you'll get a bashful beautiful piece of hard plastic with high glass transition temp. Sorry no photos, I'm currently 3 floors away from the finished products and I'm not getting out of bed to go take photos. I have never used ASA before, I've printed with abs, nylon, nylon-cf (nylonX), petg, pla, petg& pla-CF.... pretty much everything but ASA. I expected something similar to nylon but instead it is very very rigid, definitely recommend a hardened nozzle. It printed similar to Nylon-X. It is extremely rigid, very tough, has a high heat resistance. And it printed easy, really easy. I didn't have a tough trial period. Obviously, enclosure but my enclosure is a lack setup with fiberglass. It is sealed with silicone so there is no everyone escaping of heat but the heat is strictly generated by the printer, the bed mostly. I use PEI with aquaflow hairspray (I'm old school, been using it since 2016). I have a total off 9 FDM printers, 3 SLA. 3 of my FDM are enclosed, 2 of which are lack endorse based. I ensure they were built to the of their capability, it doesn't quite compare to something like a K1C or bamboo labs enclosure but the point is, this stuff, you could take an endure 3 (upgraded hotend) and throw a cardboard box over it and it'll print. Keep your expectations realistic, don't go thinking your going to print this at 120mm/s but 60 is fine, as long as you have a proper setup. Not bragging but I run PLA at 175-250 @ 5k accel on a 350x350 bed, just pointing out a properly set machine will perform for what you build it for. A standard ender 3v2 with a good hotend week leave you with amazing quality prints. Oh, DRY IT OUT, EVERY TIME. Print from a dryer. It matters. But it is wonderful.

O**R

Worth Every Penny

I have had nothing but success with this filament. I had tried to use a very similar filament from Ambrosia Filament in their Dolos filament line called Titanium Anno, and I had nothing but issues with nozzle clogging, stringing even after being dried for over 24 hours at 70C and poor overhangs. Unlike that filament, this Flashforge ASA Burnt Titanium has printed extremely well, little to no stringing, incredible overhangs and bridges. I have dried and ran the same filament settings, apart from the shrinkage compensation, as the Titanium Anno filament and have had incredible results. I will be buying more of this filament to stock up. Really wish they would expand their ASA line, as well as their multimaterial ASA line to include a color similar to the Cool Grey Pearl and Prince of Purple that Ambrosia Filament has. I would buy those in an instant.

S**S

Excellent. No lifting or stringing.

Impressive! I've been using another brand for all filament and have been happy. But, the ASA was giving me problems with lifting off the plate on corners and stringing. Just printed my first part with this and 250c Hotend and 100c bed...and no problems at all! Sometimes, ya just gotta spend a few extra bucks for quality.

L**R

UPDATE: Use of 60+ degree enclosure makes this a ton better, amazing finish

Update: After a lot of tweaking and building myself an enclosure with heated bulbs to get it at stavle 60+ temps , i managed to print what by all intents and puposes shouldnt have printed on a bed slinger (BL A1) , see last photo , superb but as i said , layer adhesion is t the greatest and you absolutely need a heated enclosure for anything higher than a few inches...use of rafts recommended I really have nothing bad to say about flashforge themselves , as ove used a lot of their filament , and this is the first one im utterly disappointed in, maybe i got a bad roll but im half a roll into it , and nearly 20 test cubes and prints , ive even built myself an enclosure and it doesnt really help ..first off if i try to print this at 240 i get bubbling , at best i can force 90% cooling and it mostly works but i can tell it doesnt like it being that hot , yet at 235 i get delamination( poor layer adhesion) so bad that i can literally snap part in half and then peel off a layer at a time Ive tried everything with this ASA burnt titanium but unless it really absolutely needs a +50 degree enclosed space ...i literally cant print anything of use on this thats not decorative at best , i get a perfect looking benchy or test cube...that i can literally crush... Test cubes from left to right show different temps, left most being 235 and it printed pretty good , but on bigger parts all i get is brittlenes similar to printing with matte pla , im positive its dry as you can see it prints with a great finish at right temp....just cant get thing to stick to itself....

J**M

Looks great, works great

Used this filament for some cosplay armor and it turned out great. I really didn't have to do much to get it going off basic settings. Its been strong and durable for everything we have put it through. I have had no issues with it at all.

A**N

Print goed en ziet er uitstekend uit. Uit de verpakking gehaald en gedroogd in Polydryer voordat ik het heb gebruikt. Ik heb een Bambu P1S. Instelling: Generic ASA. Shrinkage gemeten: X-as 99.44% en Y-as 99.56%. Gemiddelde shrinkage 99.50%.

C**N

Le filament Flashforge ASA était parfois mal voire très mal enroulé mais toujours de qualité bonne qualité. Cette fois il est aussi bien enroulé. Je suis très content de mon achat et je recommande ce matériel. Je n'ai jamais perdu une pièce imprimé en ASA de Flashforge à cause de mauvaise qualité de matériel. Sur mon Bambu X1C il s'imprime aussi bien que du PLA avec le même résultat esthétique.

R**Y

Lagre prints works best. Overhangs is a problem as many have mentioned. I would buy a diffrent asa next time

D**H

Great filament to print with. I purchased the natural colour. I will be buying this again

A**I

Bought 3 rolls of white ASA so far, and I am extremely happy with it. I've used it initially to print hooks that wrap around wooden posts and are held in place with living springs. Made about 30 of them and now, over a month later, they're still gripping tight. Mechanical properties are excellent and the color is perfect and uniform. Bridging is excellent (not as great as PLA, but this may be due to my slicer) and supports are easy to remove. I use PVP glue to help with bed adhesion of PEI spring steel bed, and this is enough to stop the warping (which would otherwise be bad; this is ASA after all) of items with large footprints (such as openGrid bases). The rolls have come dry and, with the default Generic ASA/ABS profiles on Bambu Studio and Orca Slicer, it prints perfectly and I get no stringing. Bambu Lab P1S (ObXidian 0.4 hotend) and Elegoo Centauri Carbon (standard 0.4mm hotend) print it with the same settings: 270C hotend, 100C bed, no fans, 40 mm3/s max flowrate (can be pushed higher; the filament is NOT the limiter)

Trustpilot

5 days ago

3 weeks ago