Customer Services

Copyright © 2025 Desertcart Holdings Limited

🎨 Elevate your craft with precision pressure painting power!

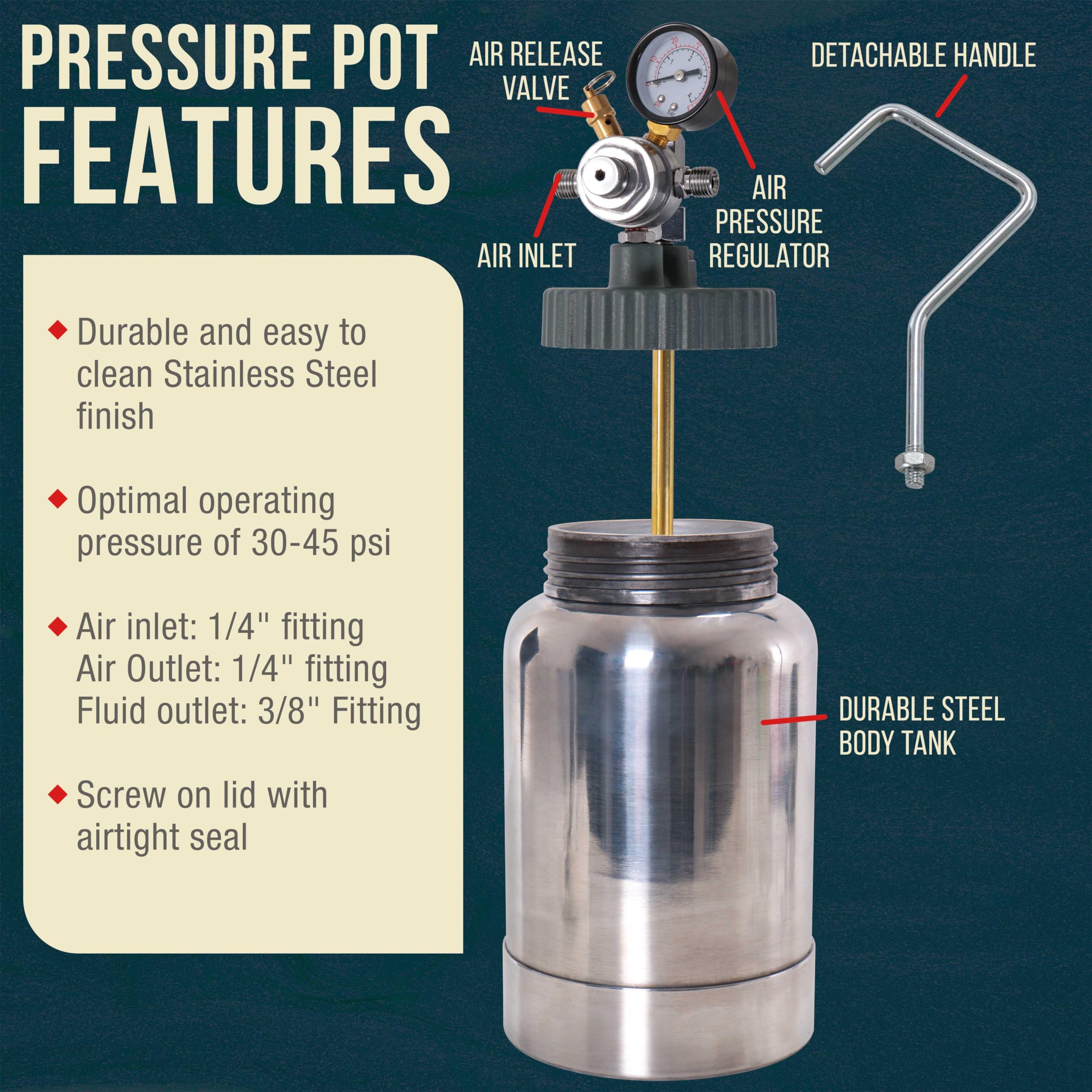

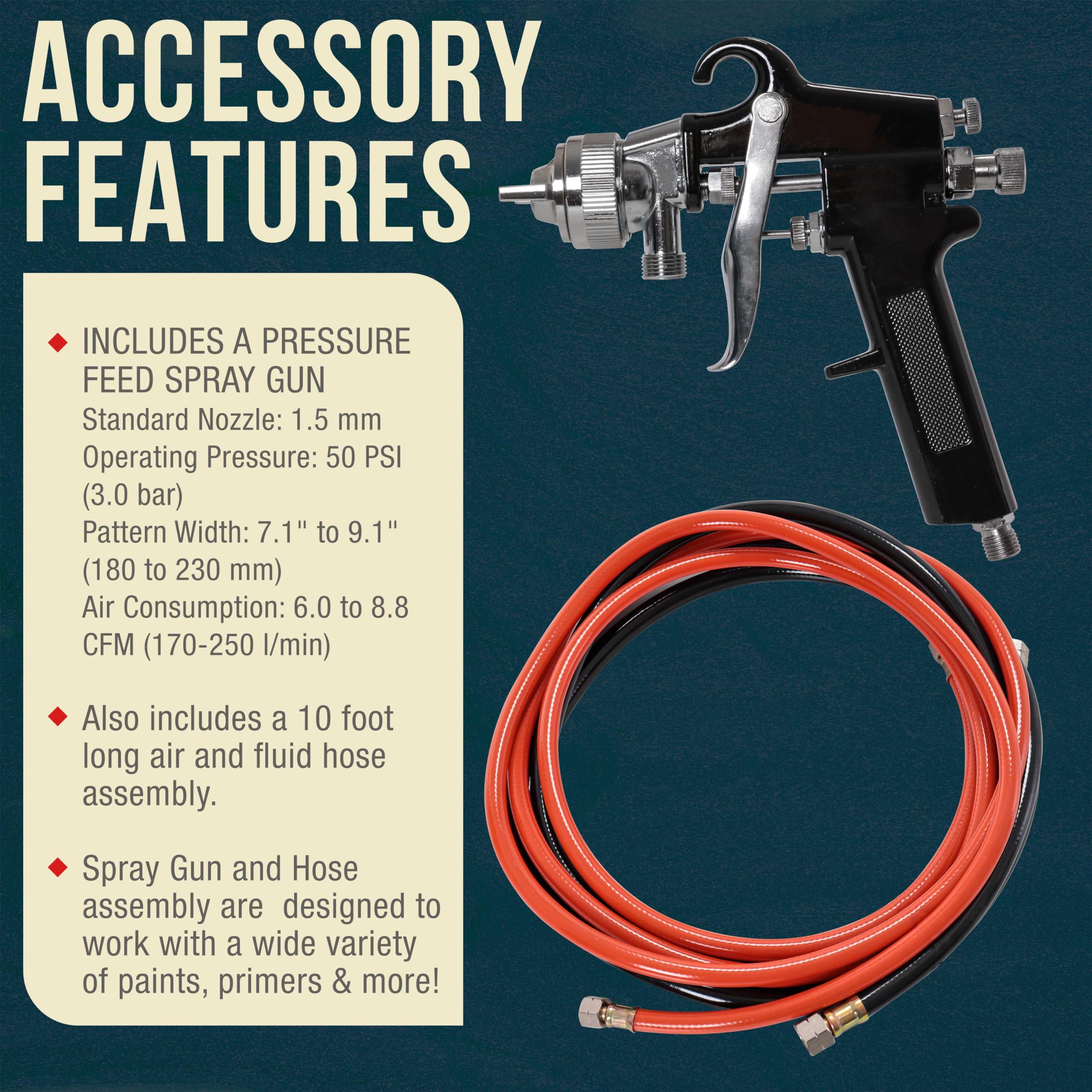

The TCP Global 2 Quart Heavy Duty Steel Pressure Pot Paint Tank is a robust, air-powered painting system designed for medium-volume commercial and autobody applications. Featuring a durable alloy steel tank, a precision 1.5mm spray gun, and a secure screw-on lid with regulator and pressure gauge, it delivers consistent, leak-free performance compatible with a wide range of coatings.

| Material Type | Alloy Steel |

| Color | Red, Silver, Black |

| Style Name | Pressurized paint pot with hand-held spray gun |

| Tank Volume | 2 Quarts |

| Hose Length | 5 Feet |

| Power Source | Air Powered |

A**N

Great Pot! Here’s how to convert it for resin casting.

This pot is a great value and perfect for turning into a pressure pot for casting resin and these are my instructions on how I converted it!This pot comes with almost everything you need to convert to a pressure pot for resin casting. There are a handful of other items you need in order to convert. You can find them all here on Amazon or at your local hardware store. I think I spent another 15$ Total on all these items.1/4-in NPT Mini Ball Valve3/8-in (to 1/4) Threaded Male Adapter Bushing Fitting1/4-in Threaded Cap Fitting1/4-in Threaded Female Elbow Fitting1/4 -in Threaded , 1/4" Male NPT Safety Valve, 60 psi Set Pressure1/4 -in Threaded NPT air compressor coupler fittingTeflon or Plumbers tape1st thing is to remove all the fittings from the lid. Including the pipe that goes down from the lid into the pot. All these parts were extremely difficult to remove, as they should be as this thing is made to hold paint under air pressure! I had to use a vice in order to get all the parts off. And even had to cut one of the fittings off with my Dremel. It was the hardest part for sure.Once all the parts are off clean the two holes with the included brush. There will be a lot of pipe glue that you will want to get off.Next thing is to wrap Teflon tape around all the male threads. This means on all 3 sections of the included T pressure gauge, on the 3/8-1/4 reducer on the air pressure fitting and on the safety valve.Both holes look similar, but they are not the same size/thread. One is a 1/4 and the other is 3/8. You will want to use your 3/8 to 1/4 reducer on 3/8 hole. Use a wrench to make sure the reducer is securely attached.Now let’s talk about the T shaped gauge that comes with the pot. Wrap all 3 male threaded parts with Teflon. On one side of the T connect the 1/4 cap, and on the other side screw on your female elbow. To the elbow you want to put your ball valve(again Teflon all the threads) and to the ball valve goes the air pressure fitting. Make sure these are all tight with a wrench (not just hand tight)Now you want to screw in the bottom of your now complete T gauge assembly to the 3/8 to 1/4 reducer you have already installed on the lid.So all we have left is the 1/4 inch hole in the lid. All we need to do on this one is screw in the 1/4 inch safety valve (Teflon again)So now you should be assembled!It’s worth saying again. All joints MUST have Teflon tape so the air doesn’t leak and you MUST screw them on with a wrench as tight as it will go. A pressure pot can explode if not assembled correctly.Here are some tips on filling with air.When you are filling you will need to have double the amount of pressure (psi) in your air compressor tank than you want to fill the pot to. So if you need 40 lbs of psi in the pot you will need your compressor tank to have at least 80lbs. If you don’t you will notice that the pressure will even out and stop filling.Attach the lid and screw down the clamps opposite from one another at the same time. This keeps the lid level and prevents leaks.If you are losing pressure you can spray the joints with soapy water, where there are bubbles there are leaks. Empty the tank using the ball valve and tighten your joints or take off and use more Teflon before attaching again..Keep the ball valve closed while you are attaching your air compressor hose, and slowly open so you don’t knock over your molds inside the pot.Always use the ball valve to control the release of air. Do not take off the lid while the pot is pressured.Hope this helps!! Good luck!

A**R

You get what you pay for

The product itself works wonderful. The gun is cheap as can be. This is good for small projects small fences. I use it in an industrial situation for the price. It is a good product

J**.

Rediculas! Industrial adhesive on all the treads!

This is beyond stupidity. If you EVER need to do anything to the regulator, all you can do it throw it away and go get another one. Someone thought they were real cute when they used some sort of industrial adhesive to put the 1/4 NPT connectors on it. I have completely destroyed the regular and everything connected to it trying to put a different adapter on it. The screws that hold the center together bent before the treads on this connector gave out. The gage is rattled apart and bent on the inside. The connector is so marred up you can not connect anything to it or take it off to replace it. The actual part that acts as a regulator is bent internally and is non-operational. There is nothing salvageable on this POS other than the scrap metal it is worth. Nothing comes apart on this thing for cleaning. this thing was a waste of money. I could have gotten a much better one for the same cost that would actually allow me to change connectors and clean it.

A**.

Great value

The pot is well made and works perfectly. It’s very heavy but with the wheels that’s not an issue.The only downside my old pot allowed me to sit the whole gallon of paint in it but this pot doesn’t allow for this.

A**.

Pretty good actually

Love this setup for my business! The spray gun is a little cheap but some fine tuning and it works just fine until I can get a better one. The tank is well built. The only bad about this product is the hose that come with it are junk. I bought longer hoses and I'm glad I did way better quality than what came with it

P**R

It's heavy duty, and modifiable for expoxy resin

I bought this for my wife for pressure treating epoxy resin. It requires a bit of modification to make it useful for this purpose. This is what I did:1. Took the pressure gauge out of the air inlet, and added a 1/4" quick connector for my compressor. There are now three ball valves: one for pressure input from compressor, one for closing off the pressure to the pot, and a third for releasing the pressure. This could be configured differently, it was just the easiest way to do this considering how the product was configured when I got it.2. Took the hand crank mixer out and replaced it with a 4" X 5/8" bolt, 2 - 5/8" washers, and 2 - thick rubber washers. See the photo for how this is set up.3. Took out the paint outlet valve and replaced it with a Kobalt filled gauge.When I first pressurized the tank, it was leaking out of the safety valve. I'm not sure why because I never touched the safety valve? Anyway, I managed to tighten the valve up and no leaks. I then pressurized the tank to 45 PSI and I let it set overnight. When I woke up the next day, I still had 45 PSI so it's good to go!

J**M

I give it 3.5 stars

I'm giving it 3 stars instead of 4, because I can't give it 3.5.The pot should have come with a regulator for the air side of the gun. I added one and it made night and day difference. Considering the cost of a small regulator, it should have been included with the purchase. The pop off valve is a little iffy as well. It seems to let loose at less pressure than what is claimed in the instructions. I find that running the tank at 10-20 psi is more than sufficient to push single stage enamel. I run the air at the gun at 40 psi. This 1.5 tip seems to like the higher atomizing rate. The tank seals nicely without allot of effort on the wing nuts.The regulator for the pot pressure seems to work and is fairly close with another regulator I checked for accuracy. I have painted two grain wagons with this pot. I have shot 4 gallons of enamel through it. The 1.5 tip sprays single stage primer and enamel well. The gun has a wide fan. It will hold a gallon bucket of paint inside so you don't get the pot dirty. I can see in the future I will be buying longer hoses, 10 feet is not enough when painting large equipment.For the money and a few tweaks, this is a good starter pressure pot.

Trustpilot

2 weeks ago

1 month ago